How to deal with the scorching phenomenon of laser cutting machine

Published:2021-07-06 Browse:270Editor in charge:DNE LASER

As we all know, a lot of heat is generated during sheet metal processing. If the heat of the fiber laser cutting machine cannot quickly diffuse into the air, it will cause the edge to burn. For example, when a metal laser cutting machine is stamping, due to the small thermal diffusion space and the concentration of heat, the temperature of the workpiece is too high, resulting in residual edges. In addition, during the processing of thick plates, molten metal and heat accumulate on the surface of the material, and the lack of auxiliary airflow makes it impossible to separate the heat, resulting in excessive burning of the metal plate and edge burnout.

So how to solve the problem of burnt and residue of metal laser cutting machine?

How to prevent the influence of oxidation reaction heat is the main idea to solve the problem of carbon steel punching burning. This method can be used for laser cutting. At the end of oxygen blanking, the auxiliary gas is used to delay the release of air or nitrogen from the power switch. This method can handle 1/6 of the thickness of the sheet metal punch.

Low-frequency pulse cutting conditions and peak output power conditions have the characteristics of reducing heat output, which can optimize cutting conditions. This working condition is a single-pulse laser beam with high peak output, high energy intensity, and low frequency, which can reduce the accumulation of molten metal on the surface of the material and the heat output.

In short, the way to deal with this phenomenon is to increase the working pressure of the auxiliary gas, set the maximum output and low-frequency pulse standards. When an auxiliary gas is used in the air, it will not burn like nitrogen and will not produce bottom residues.

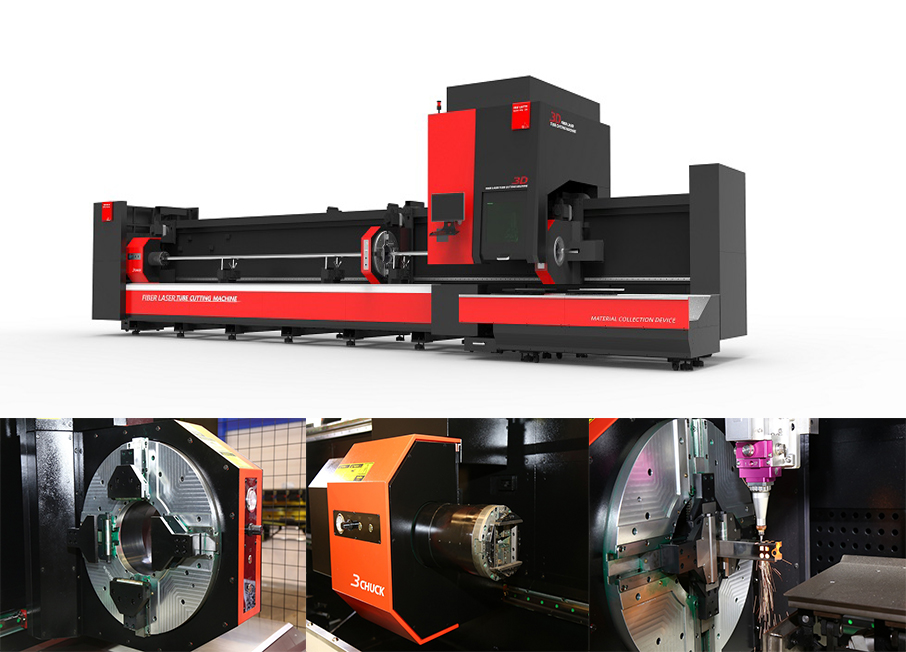

The fiber laser cutting machine uses a fiber laser, which has a lot of heat. Under the action of this laser, effective cutting can be achieved. The speed and accuracy are very high, which is why so many people are willing to choose. The plasticity of the fiber laser cutting machine is very strong. In the cutting process, there are many methods.

For example, the plane cutting has been inclined and so on, but no matter what kind of cutting is performed on the fiber laser cutting machine, the flatness of the surface can be guaranteed. This is why laser cutting technology is more popular.

Bystronic (Shenzhen) Laser Technology Co., Ltd.

Bystronic (Shenzhen) Laser Technology Co., Ltd.