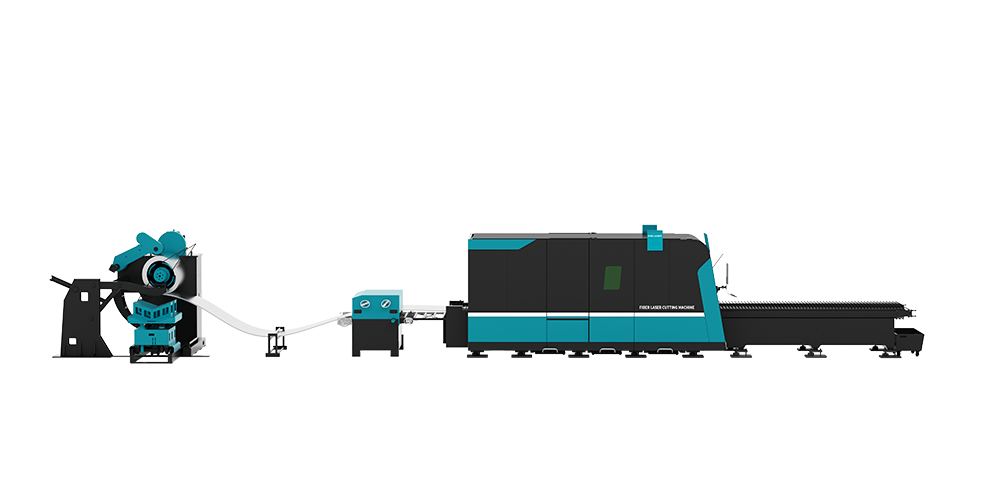

Laser Cutting

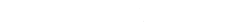

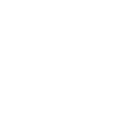

D-Speed

New

High-Performance Laser Cutting Machine

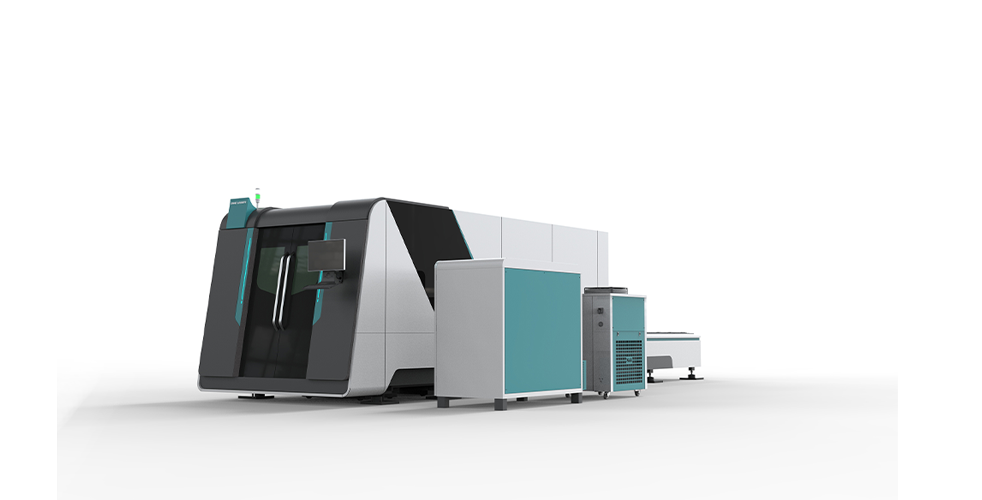

D-Power

New

Ultra-High Power Fiber Laser Cutting Machine

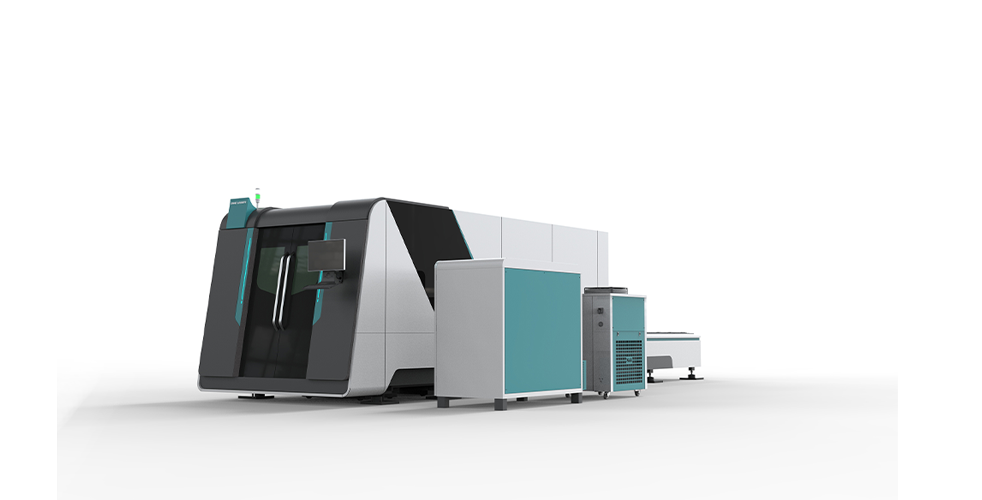

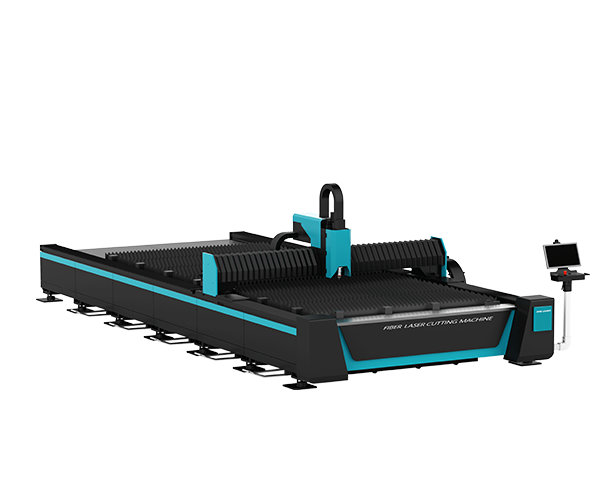

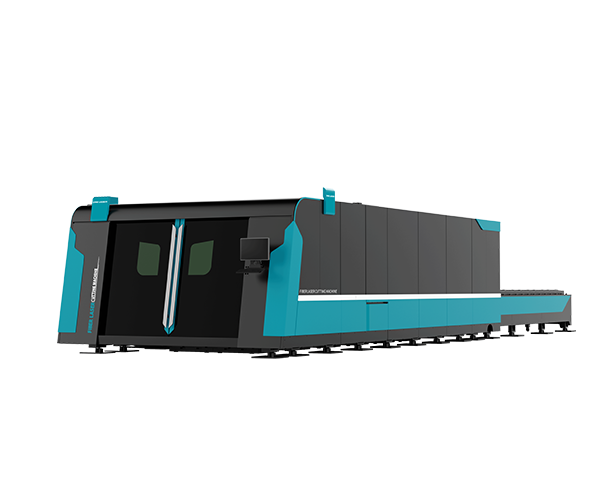

D-Energy F

Hot

Fiber Laser Cutting Machine

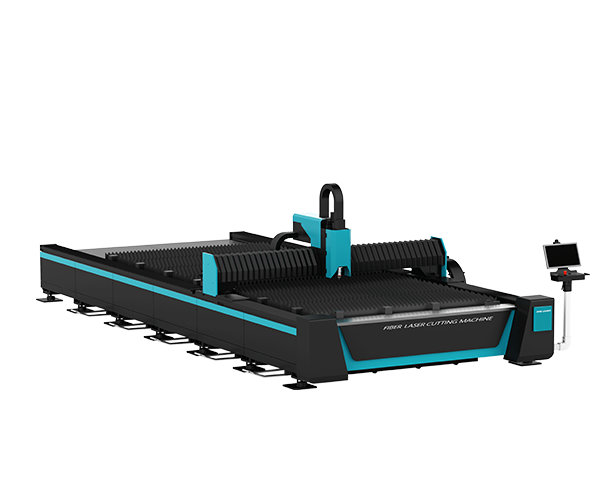

D-Soar

Ultra-High Power Fiber Laser Cutting Machine

D-Soar Plus-PG

Fiber Laser Cutting Machine with Bevel Head

D-Soar Plus-G

Ultra-High Power High-Speed Fiber Laser Cutting Machine

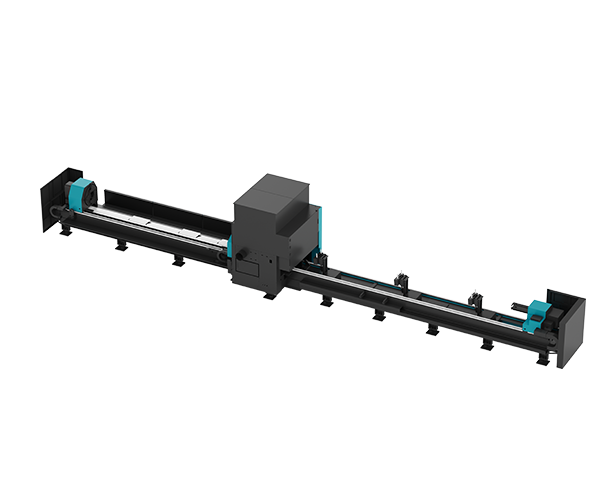

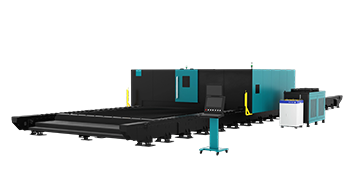

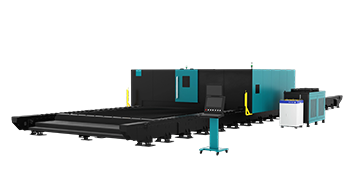

D-Giant

Big Size Ground-Rail Fiber Laser Cutting Machine

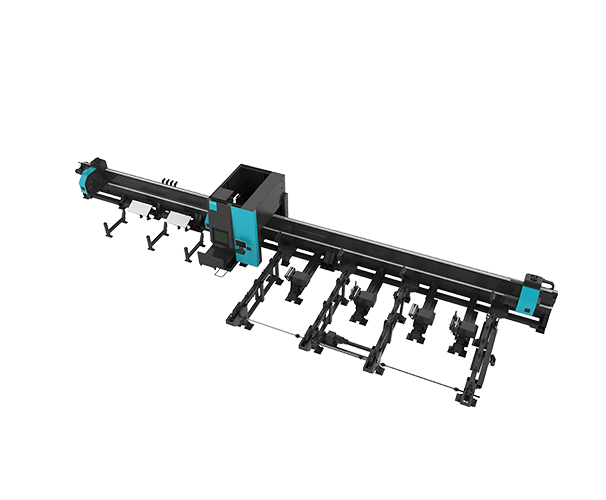

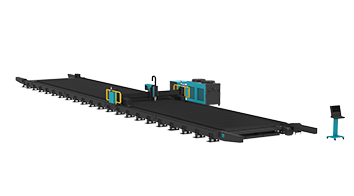

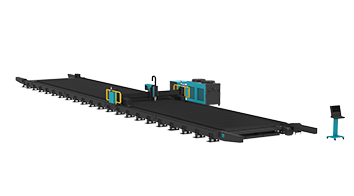

D-Giant F

Big Size Ground-Rail Fiber Laser Cutting Machine

Maybe you can search for

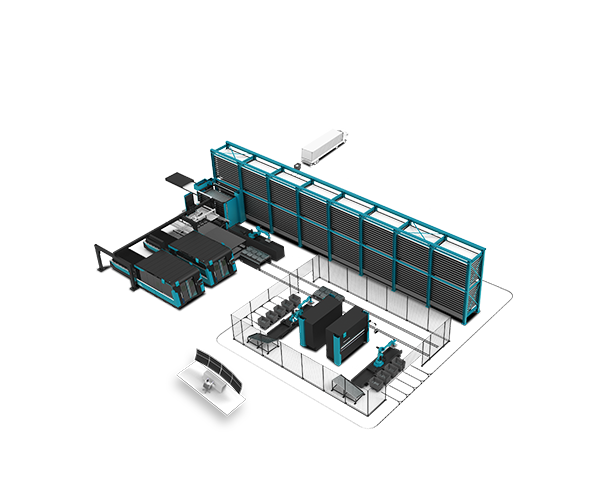

Company Overview

DNE LASER (Guangdong) Co., Ltd. (Brand name: DNE LASER), a

wholly owned subsidiary of Swiss Bystronic Group, is headquartered in Shenzhen with its production base located in Nanhai, Foshan.

wholly owned subsidiary of Swiss Bystronic Group, is headquartered in Shenzhen with its production base located in Nanhai, Foshan.

View more

Contact Us

For all business inquiries, partnership discussions and feedback,

please contact us via website form, 24-hour service hotline or email. Our team guarantees a prompt response within one business day.

please contact us via website form, 24-hour service hotline or email. Our team guarantees a prompt response within one business day.

View more

Join Us

We welcome talented professionals worldwide, offering attractive

pay, benefits, and clear career paths. Our collaborative culture drives innovation. Whether an expert or rising star, you'll thrive with us.

pay, benefits, and clear career paths. Our collaborative culture drives innovation. Whether an expert or rising star, you'll thrive with us.

View more

Search

Close